The Facts About Sheroz Earthworks Revealed

The Facts About Sheroz Earthworks Revealed

Blog Article

The 6-Second Trick For Sheroz Earthworks

Table of ContentsNot known Facts About Sheroz EarthworksThe Single Strategy To Use For Sheroz EarthworksThe 6-Second Trick For Sheroz EarthworksExcitement About Sheroz EarthworksThe Facts About Sheroz Earthworks Revealed

Yet obtaining the ground to simply the appropriate level is no simple task. 3D device control systems enable automated blade control, guiding the dozer blade to precisely the appropriate angle at precisely the best places. This system boosts accuracy and effectiveness by a big margin. By making certain degree ground, it makes best use of safety and security for workers once the structure process begins.Scraping features rather like sleeping, but on a much finer and more precise range. While dozers push large quantities of dust off the beaten track to even out the ground, scrapers return over the location to fine-tune it. trimble parts. Maker control for scrapes features simply like for dozers, routing the blade to simply the right setting to accomplish a flawlessly degree cut.

Machine control can include value to numerous agriculture jobs, consisting of: You can use the modern technology to without effort keep track of and map area information in actual time, making browsing and leading your tools simpler than ever before. Trick functions include aided steering that gets rid of much of the burden from the driver, water monitoring, return monitoring and video camera input.

Device control is sturdy enough for heavy area usage and uses the versatility to execute numerous drainage system applications. Achieving maximum vertical accuracy is essential when grading and creating land for farming. Machine control systems can manage this tough application quickly and effectively, enabling you to enhance performance and decrease downtime in the field.

Not known Facts About Sheroz Earthworks

Experience measurable renovations in important areas like machine and property organizing, fuel intake and preventative maintenance. Strengthen task site safety and other essential processes by enhancing accuracy and integrity in important mining operations. Get rid of incorrect hand-operated field dimensions and enhance reporting versatility in your geotechnical and environmental tracking programs with these advanced data-capturing remedies.

No matter what the focus of your most current building task is, you can profit from machine control. It can fine-tune your progressing and develop your digging, and it can do all of it while giving you feedback on where each rover gets on the site at any provided minute. As a movie director, you can make use of the system software application to see the entire website at the same time and observe every place that is being altered in real time.

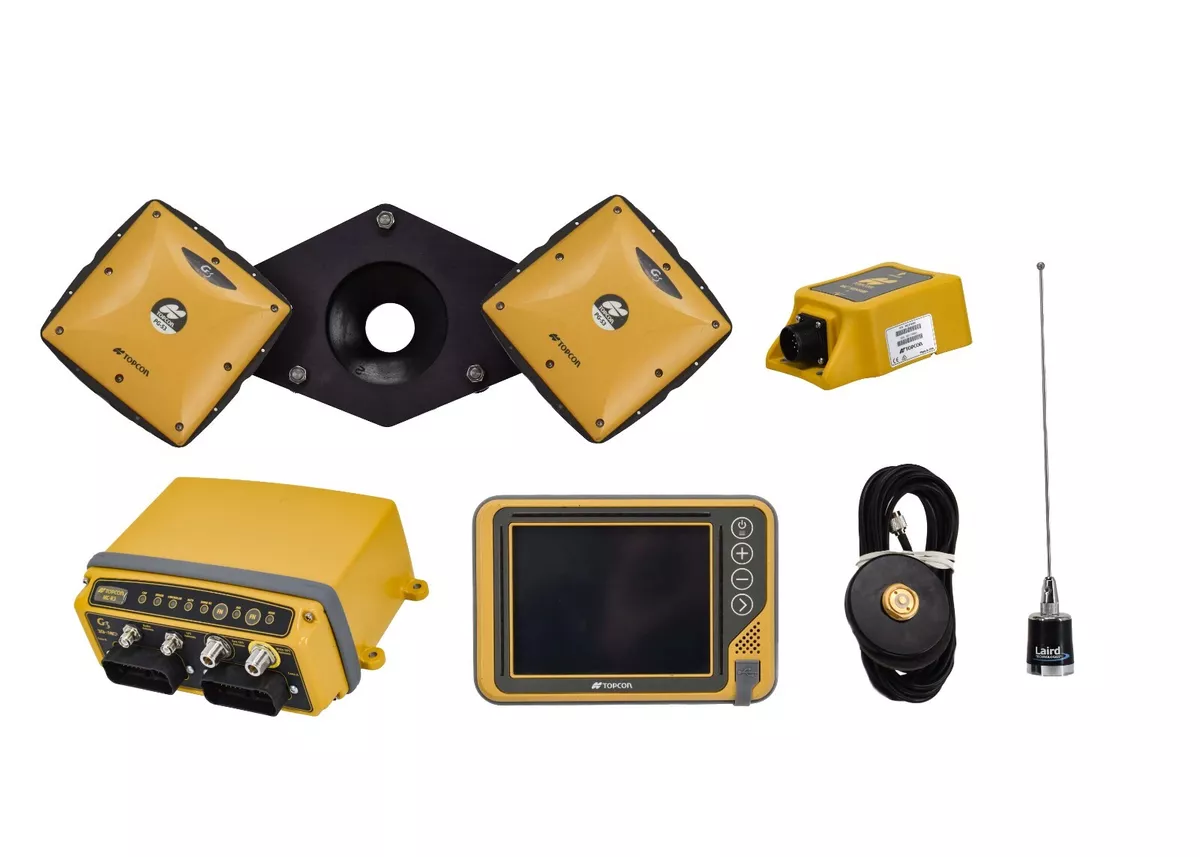

SITECH Southwest can obtain you the machine control system you require to revolutionize your construction procedure. As an accredited Trimble dealer, we supply top-quality equipment for all the building and construction refines noted above.

The Definitive Guide for Sheroz Earthworks

For this to function, revolving lasers were established click here for more to beam that can be grabbed by sensing units positioned on dozers or graders. This provided operators the fundamental info they required for their equipments. Yet, in contrast to modern-day maker control, these early systems were still extremely limited at providing a full and exact image and were also frequently as well expensive or complex.

It is obvious that there is an absence of fresh talent entering the field. In specific, service providers have problem attracting young individuals and, as an outcome, there are fewer operators going into the career. Should this trend continue, the market will certainly be entrusted a lack of skilled and reliable operators, which suggests that the quality and performance of projects will certainly be affected by a significant skills gap.

Going beyond simply giving operators with a visual guide to container or blade setting, automated equipment control relocates the blade to quality by talking with the machine's hydraulics - trimble repair parts. Unlike with regular maker control, automated maker control innovation places the duty for accuracy and rate securely in the hands of performance-enhancing modern technology

When taking a look at the existing building landscape, it is clear that, despite its considerable benefits, maker control automation is not being adopted across all machines at an equal rate. Actually, although automation is being embraced on machines like and dozers, the uptake has been much slower for excavators, with the adoption price of automated equipment control on these makers still approximated at around 10% in Europe in comparison to a rate of over 50% for dozers.

Not known Incorrect Statements About Sheroz Earthworks

Today, an increase in performance on excavators can be noted as raised precision and decreased over-digging being relatively very easy to confirm. It is clear that the industry currently needs to reassess the demands for excavators. With the needs for productivity increasing and a lack of experienced operators, construction requires to welcome the advantages that spending in automated device control can bring.

If you are wanting to boost your efficiency with today's modern technology we are here to help. Your existing team can be trained to perform all facets of the laid out and grab tasks of the everyday site needs in a no rubbish technique.

As expected, the excavator drivers are under a tremendous pressure to deliver an optimum performance while trying to attain their performance goals at the same time. That is why all type of aid and improvements are greater than welcome regarding raised accuracy and optimal production. As always, innovation is the trick.

The Basic Principles Of Sheroz Earthworks

Report this page